Underground or open pit. Long wall or high wall.

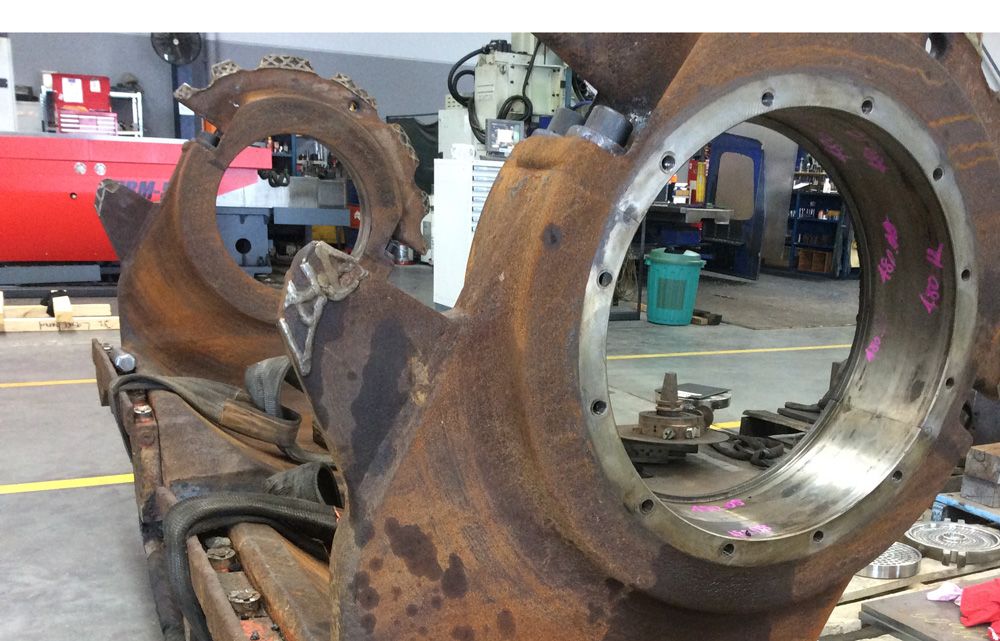

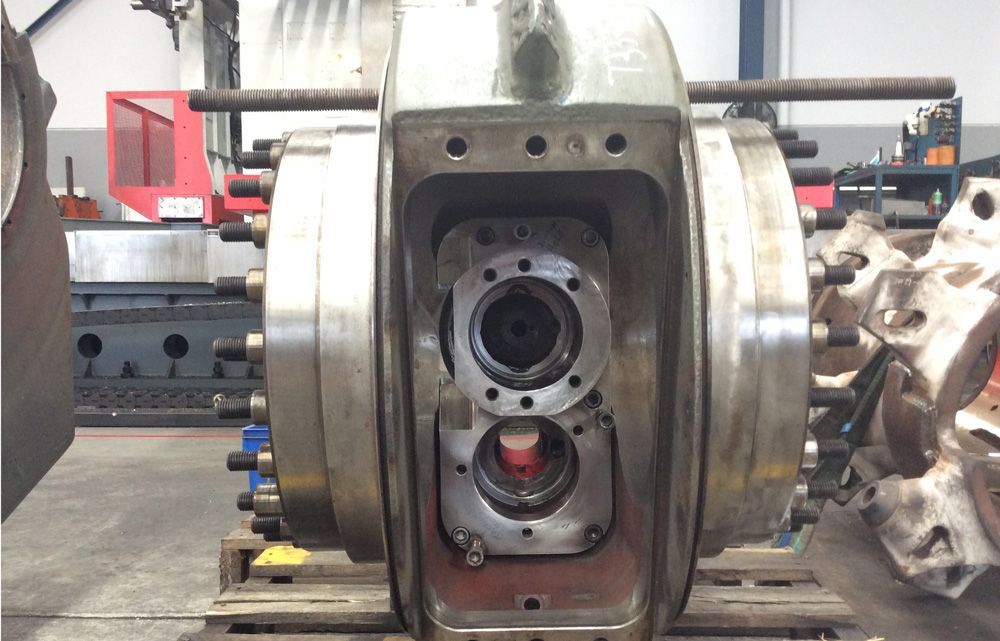

Mining involves equipment and component wear. Headers, Haul trucks, G.E.T., Grader blades, Cylinders, Pumps, Valves; The list goes on. Output depends on continued availability.

LaserBond surface engineering technologies have been developed to improve availability and productivity by extending component life. When applied to production-vital components these same technologies also increase performance, extend plant and machinery operational life, increase reliability, reduce component change-outs, increase resistance to wear and corrosion and reduce overall operating and maintenance costs. This will improve availability.

Benefits:

Reduced Cost per BCM

Laser Cladding is designed to maximise the availability, improve the capabilities and extend the operational life of production equipment and components. As an integral part of an extraction process it will improve operational efficiency and effectively reduce cost per BCM. And that’s a production bonus.

Improved Site Safety

Laser clad production equipment and components have a longer operating life. And that means less maintenance, repair or replacement time. And that means a reduction in the time maintenance terms face the potential for workplace accidents. And that means improved site safety.

Improved Performance

Nameplate performance and reliability are two of the benchmarks for production equipment. The longer and better equipment performs the better the result. LaserBond surface engineering can (and will) improve the reliability of production equipment. And by improving the reliability and maximising availability, performance and productivity will be improved.

Case Studies

Our Stories… an enviable reputation built on solid performance.

Large dump trucks are used extensively in the Australian mining

Underground mining is a tough environment – dusty, damp, vibrations,

Underground mining is a tough environment – dusty, damp, vibrations,

Road headers are flexible rock cutting machines widely used in